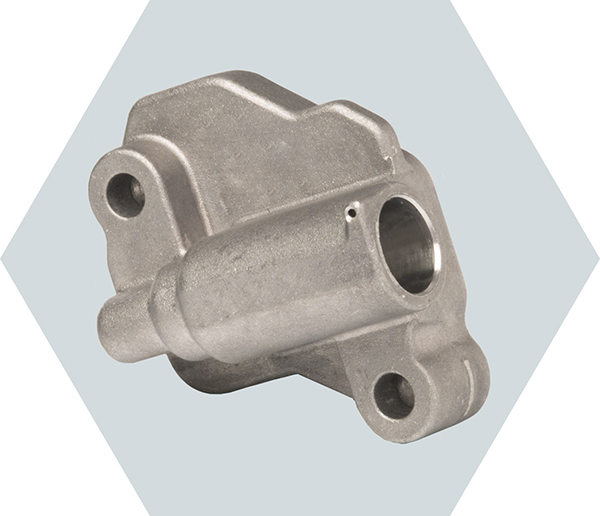

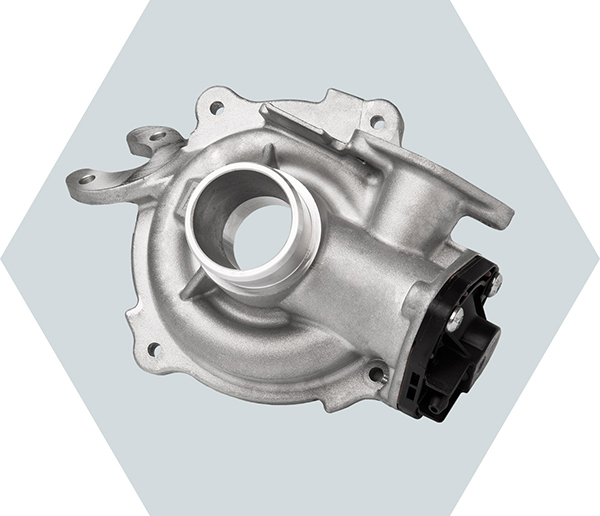

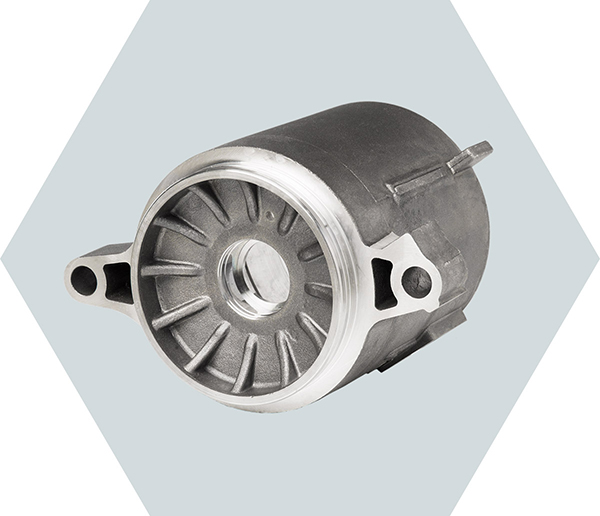

ALUMINIUM FORMING – PRESSURE DIE CASTING

Pressure die casting is an industrial casting process for the series or mass production of structural parts. In pressure die casting the molten mass is forced under a high pressure of approximately 10 to 200 MPa and at a very high mould filling rate of up to 12 m/s into a die-casting mould (casting mould, cavity), where it then solidifies. What makes the pressure die casting process so special is that the work is carried out with a permanent mould, i.e. without a model. The result is that for a series of identical components, the mould only has to be produced once.

- Fully automatic casting cells with:

- closing forces of 250 t to 1,650 t

- unit weights of 0.050 kg to 8 kg

- Mechanical machining

- Surface coating (chrome plating, polishing)

- Own tool design and construction

- Mould filling and solidification simulations